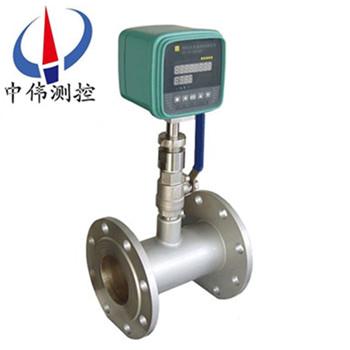

Pipeline thermal mass flowmeter

ZW - RSLG seriesPipeline thermal mass flowmeterSpecially designed for industrial gases for a variety of management and control.This series of instrument can provide intuitive mass flow information, friendly user interface design (RS485/4 ~ 20 ma/pulse, etc.) can be easily for data processing.The product can be applied to from 25 to 100 mm diameter pipes, and the precision can reach + FS (1.5 + 0.5) %, working environment temperature is 20 ~ 60 ° C -, big work pressure 1.5 MPa.Packaging technology to ensure that the health index of the flowmeter, the gas measurement can be applied to beverage food industry.

Second, the working principle:

ZW series - RSLG pipeline thermal mass flowmeter is the use of heat transfer technology as the foundation, realize the gas mass flow measurement.The flow measuring probe with two platinum resistance sensor.They are put in fluid, one of the P by heating power, make its temperature rise to T 1, another not heating, used to monitor the medium temperature, set to T2.So the temperature difference between the two sensors delta T = T1 - T 2.In flow is zero, the delta Tzui big, with the increase of mass flow rate Q, sensing element T1 heat is carried away, T1, delta T.So the heating power between delta T P, temperature difference and mass flow rate Q will produce a certain relationship.

Under the available type said: P/T = K1 + Δ K2F (Q) K3 (1) the type of K1, K2, K3 is related with the physical properties of gas constant.

As you can see on type by measuring the heating power P, the change of temperature difference delta T mass flow rate Q can be obtained.For the simplified and practical work is the heating power P or temperature difference in the delta T a remain unchanged.The former is called the constant power type and the latter is called the constant temperature differential.For ZW - RSL thermal type gas mass flowmeter, according to the different requirements and choose among them a way to work.

Applications:

1, utilities - electricity, gas, water treatment monitoring;

Gas pipeline;General system;Biogas;The gas;Natural gas;Liquefied petroleum gas.Preheated air boilers.

2, oil and gas industry;

Energy exchange;Fill well gas recycling;Gas metering;Gas quality analysis;Gas leak test;Natural gas measurement;The torch gas monitoring.

3, the power industry;

Fuel gas measurement in the process of gas distribution in the system.All kinds of gas in the boiler and auxiliary system of measurement;Gas burners in the gas measurement;Hydrogen measurement;A wind power plant in the blast furnace, the secondary air measurement.

4, chemical industry.

Flue gas circulation monitoring;Sampling system of gas flow metering;Induced draft fan of gas flow metering;Fertilizer plant ammonia measurement;The battery factory all kinds of gas flow measurement.

5, and metallurgical industry.

Steel mills gas measurement;Iron blast furnace gas measurement;Coke oven gas measurement;Rolling mill reheating furnace gas (blast furnace gas, coking coal gas, natural gas, etc.) of the measurement control;The heat treatment such as quenching furnace control of hydrogen, oxygen, nitrogen and other gases.

6, pulp and paper industry.

The measurement of the gas in the wastewater treatment system;The flue flow monitoring;Boiler air recycling twice/three times;Boiler gas and air supply air measurement.

7, food and pharmaceutical industry.

The addition of processing operation in the fresh air;Carbon dioxide from the brewery processing;In the hot air flow in the bottle sterilizer;Thermal oxidation in the process of gas flow measurement;Ventilation system;Boiler air intake, exhaust gas and process control.

8, environmental protection;

In the process of biogas utilization gas measurement;Sewage treatment process of aeration tank gas measurement;Funnel flue exhaust monitoring SO2 and NOX emissions.

9, other industries;

Factory compressed air measurement;Pulverized coal combustion process of powder/gas ratio control fuel;Cement industry vertical mill discharge steam flow control.

Four, the main features:

1, the stability of high technology platinum RTD sensors;

2, using a proprietary technology balance encapsulation structure, the medium temperature compensation;

3, proprietary algorithm, which can realize high linearity, high repeatability, high precision;

4, than 1000 wide range: 1, can according to user requirements can be expanded;

5, can realize the big diameter small flow measurement, zui small flow can be measured as low as zero, resolution of 0.001 m/s;

6, no moving parts, vibration effect can be ignored;

7, 1-2 d straight pipe requirements is not high;

8, has nothing to do with the medium temperature and pressure;

9, proprietary algorithms by high temperature, medium temperature can be up to + 510 ℃;

10, using the algorithm of high humidity, realize high precision measurement;

11, the traffic signal type in 12 dynamic correction, the built-in 10 point correction;

12, on-line dynamic correction current/voltage output;

13, is not sensitive to small particles such as dust;

14, loading and unloading, the online does not block the maintenance is convenient.

Five, the technical parameters:

1, measuring range: (0.05 ~ 80 Nm)/s (standard state is 20 ℃, and 101.33 KPa);

2, measuring medium: except the acetylene gas clean gas;

3, temperature range: ambient temperature: - 40 ℃ ~ + 60 ℃.

4, medium temperature: - 10 ℃ ~ + 200 ℃;

5, the accuracy of the quasi: + / - 1% of the readings;Plus or minus 0.5% full scale;

6, after sex: + / - 0.5% of full scale;

7, lose out: the instantaneous flow rate of 4-20 ma DC zui big load 600 Ω, RS232 and RS485.

8, response speed, less than 1 s;

9, the power supply voltage: 24 VDC + / - 10%;

10, mechanical connection: 3/4 NPT stainless steel fasteners;

11, sheath maerial length: 800 mm (the length of standard length, special please statement);

12, sheath maerial diameter: 18 mm;

13, straight pipe length: without strict requirements;

14 and the pressure loss: can be ignored;

15, working pressure: 1.6 MPa;

16, field display (LED) for the instantaneous flow rate on the four characters in a row, discharge to the cumulative flow line 8 characters, can be in English or metric units show that flow, accumulated flow;

17, data protection: the cumulative amount of stored in the EEROM, can be stored power (one hundred);

18, sensors and pipeline material: 316 l (optional hartz alloy C);

19, protection level: IP65;

20, transmitting unit: select explosion-proof enclosure.

Six, product categories:

Instrument plug-in and pipeline, according to the connection mode and diameter size can also be subdivided, specific as follows:

1, ZW - RSLC - 1 type plug-in base;

2, ZW - RSLC - 2 insert flange connection type flue gas flow (speed) 】 【;

3, ZW - RSLC - 3 plug in the card sets (3/4 "NPT) connection type;

4, ZW - RSLC - 4 plug-in card set + type ball valve connection;

5, ZW - RSLC - 5 + ball valve connection type plug seal body;

6, ZW - pipeline RSLG - 1 (DN40 (DN80, DN100);

7, ZW - RSLG - 2 pipeline (3/4 ", DN25);

8, ZW - RSLG - 3 pipeline (DN10, DN15, DN20A, DN25A);

Seven, the determination of upper and lower range:

1, determine the lower limit of: because the thermal type gas mass flowmeter is sensitive to low velocity, zui low measured 0.05 m/s of velocity, so don't need to be considered in the selection of floor;

2, the determination of upper limit: mainly be determined by the values of process design, general design cap of about 20% is higher than the upper limit value of the instrument, in order to improve the fault tolerance rate;

3, mixed gas range: for mixed gas, users should give the density and molar ratio (ingredients percentage of the total), and then by the manufacturer to determine the range.Generally USES air or nitrogen calibration, and then through the conversion coefficient of correction instrument;

Statement:

Range selection ceiling is limited by conditions of equipment, the high limit please contact manufacturer to determine the technical detail before purchasing.

Eight, installation options:

1, advice: diameter, 100 or less, choose pipeline installation;

Pipe diameter > 100, choose plug-in installed.

2, if the piping has been installed, do you have any flange installation, can only choose to insert installation, can be explained in order with the factory.

Nine, choice of structure type:

1, a body structure, namely, sensor, transducer, a display part of body, power supply is 220 vac or 24 VDC.Display section, is equivalent to a flow totalizer.especially display instantaneous flow and cumulative flow, set up the emergency alarm and 4 ~ 20 ma output linear signal.

2, size structure, namely, sensors, transmitter and display part of the separation, a display part of, a flow totalizer.especially display instantaneous and total flow rate, set the alarm point and 4 ~ 20 ma output linear signal.Two parts through three thread connection, so the transducer for three-wire system.

Ten, instrument output type options:

1, the linear output

A body structure of the output analog signals is a standard 4 ~ 20 ma linear signal, in the point size structure from the transmitter output unit 4 ~ 20 ma signal, linear is poorer, only again from output flow totalizer.especially signals is quasi linear 4 ~ 20 ma.

2, again from flow totalizer.especially 4 ~ 20 ma output, can set the whole flow range of a human.For example, a flow meter range of 0 ~ 5000 nm3 / h, 4 ~ 20 ma output linear signal, can set 0 ~ 3000 nm3 / h, 100 ~ 1500 nm3 / h...Output 4 ~ 20 ma.

3, cut of small signal: for some users, required excision, small signal in order to make sure there is no traffic display measured to 0 or not.

4, output filter, the gas flow in the pipeline, there is always some disturbance due to various reasons, beating performance for output figures show that the filter coefficients, increase totalizer.especially can reduce jitter, good observation.

5, communication interface, the user need communication interface, when ordering, please.

Note: all of the above project is the performance of the product must have, only 4 ~ 20 ma output flow totalizer.especially, communication interface and the number of stations for options.

Eleven, installation position and the requirement of pipe:

1, select the reasonable installation position, avoid elbow, valve, variable diameter component type fluid flow profile change.Generally requires a long straight pipe, straight long before more than 10 d, straight long after more than 5 d.Encountered special circumstances, please refer to the following icon to select zui ideal installation position, to ensure that the sensor before and after the straight distance, obtain zui ideal measuring results.

2 straight pipe, the scene can't satisfy the requirements, can be concatenated gas rectifier, in order to reduce the requirement for straight pipe.

3, in short straight pipe, elbow and valve set of conditions, such as adopting thermal type gas mass flowmeter, need some practical experience specific solution, please discuss with orders.

Twelve, sensor parameters:

Section sensor data tables (Threaded connections)

Inside diameter (mm) DN | The weight of the(Kg) | Install length L (mm) | Connection thread | The rated pressure (MPa) | |

With fitting | Without fittings | ||||

20 | 4.5 | 280 | R3/4″ | G1″ | 1.6MPa |

25 | 4.7 | 280 | R1″ | G11/4″ | |

40 | 5.0 | 280 | R11/2″ | G2″ | |

Note:DN<20mmPlease consult our company, sensor size

Section sensor size table(Flange connection)

Inside diameter (mm) DN | The weight of the(Kg) | Install length L (mm) | Flange dimensions (mm) | The rated pressure (MPa) | ||

D | D0 | N×A | ||||

20 | 6.2 | 280 | 105 | 75 | 4 x 14 | 1.0 |

25 | 6.6 | 280 | 115 | 85 | 4 x 14 | |

32 | 7.2 | 280 | 140 | 100 | 4 x 18 | |

40 | 8.2 | 280 | 150 | 110 | 4 x 18 | |

50 | 9.6 | 280 | 165 | 125 | 4 x 18 | |

65 | 10.8 | 280 | 185 | 145 | 4 x 18 | |

80 | 13.1 | 280 | 200 | 160 | 8 x 18 | |

100 | 16.5 | 280 | 220 | 180 | 8 x 18 | |

125 | 19.6 | 290 | 250 | 210 | 8 x 18 | |

150 | 29.8 | 310 | 285 | 240 | 8 x 22 | |

200 | 40 | 340 | 340 | 295 | 8 x 22 | |

250 | 56 | 370 | 395 | 350 | 12 x 22 | |

300 | 66 | 410 | 455 | 400 | 12 x 22 | |

350 | 70 | 440 | 505 | 460 | 16 x 22 | |

400 | 75 | 480 | 565 | 515 | 16 x 26 | |

450 | 90 | 510 | 615 | 565 | 20 x 26 | |

500 | 105 | 550 | 670 | 620 | 20 x 26 | |

600 | 162 | 620 | 780 | 725 | 20 x 30 | |

700 | 180 | 690 | 860 | 810 | 24 x 26 | 0.6 |

800 | 240 | 750 | 975 | 920 | 24 * 30 | |

1000 | 390 | 890 | 1175 | 1120 | 28 * 30 | |

1200 | 650 | 1030 | 1405 | 1340 | 32 x 33 | |

1400 | 850 | 1160 | 1630 | 1560 | 36 x 36 | |

1600 | 1150 | 1290 | 1830 | 1760 | 40 x 36 | |

1800 | 1500 | 1430 | 2045 | 1970 | 44 by 39 | |

2000 | 1890 | 1560 | 2265 | 2180 | 48 x 42 | |

Note: Only is given in the table1.0MpaThe pressure rating of the above1.0MpaPlease consult our company

13, selection of coding:

ZW-RSL | The thermal type gas mass flowmeter (wei measurement and control) | |||||||

The male Cheng Tong diameter | -XX | 100 said DN100 | ||||||

Type of installation | G | pipeline | ||||||

C | plug-in | 1 | Threaded connections | |||||

2 | Flange connection | |||||||

Nominal pressure | A | 0~0.6MPA | ||||||

B | 0~1.0MPA | |||||||

C | 0~1.6MPA | |||||||

D | 0~2.5MPA | |||||||

E | 0~4.0MPA | |||||||

F | 0~6.4MPA | |||||||

G | 0~10MPA | |||||||

H | 0~16MPA | |||||||

Process conditions | 0 | ordinary | ||||||

1 | Corrosion protection | |||||||

2 | explosion-proof | |||||||

3 | The high temperature | |||||||

The input signal | A | There is no output | ||||||

B | 4~20MA | |||||||

C | RS485 MODBUS | |||||||

Power supply | 1 | 220V AC | ||||||

2 | 24V DC | |||||||

14, designing order selection guidelines:

1, the thermal mass flowmeter is made up of one-piece flow converter, the flow sensor.According to the type of the flow sensor can be divided into: the plug-in and pipe sections of thermal type gas mass flowmeter.

2, one-piece thermal mass flowmeter: insert type sensor can be installed in the online, on-line maintenance.Installation process is the first outside the pipe wall welding with the external thread of the base, on the base to install 1 inch stainless steel ball valve, and then use a special tool will play the 22 mm diameter hole, pipe punching after the completion of specialized tools, finally the sensor installed on the valve and the sensor is inserted into the pipe center (insert position sensor factory have been identified).

3, if can't welding of piping material (such as cast iron, PVC, glass, cement, etc.), you can use my company's production of special fixture, the sensor is fixed on the pipeline.

4, insert type sensor for pipe diameter: DN80-6000 mm (larger diameter ordering).

5, pipe sections of thermal type gas mass flowmeter, factory has been equipped with pipe diameter of the same process piping and scene.Connection with the pipe flange connection or threaded connection.The flange standard accord with national standard GB/T9119-2000.Pipe sections of sensor for pipe diameter: DN15 ~ 2000 mm.

6, the sensor is made of stainless steel, pipe material is carbon steel or stainless steel, special material ordering.

After-sales service commitment:

1, our company sold by mass flowmeter series products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.